1. HEALTH & SAFETY POLICY STATEMENT

Genial Productions (the Company) recognises its health and safety duties under the Health and Safety at Work etc. Act 1974 and all related health and safety legislation. To this end the Board of Directors (Board), have agreed that the Board Directors (referred to as ‘The Directors Responsible for Safety (Board)) will be jointly responsible for health and safety. The Board of Directors will keep workplace procedures under constant review and liaise with the enforcing authorities wherever necessary.

In recognition of its duties to report serious accidents, incidents and occupational diseases the Company has instituted a system for notifying the Enforcing Authorities as appropriate. This supplements the statutory duty to keep records and an Accident Book (loose leaf forms) that are available for inspection by an Enforcement Officer.

Specifically, compliance with all health and safety legislation means that Genial Productions will

Provide and maintain a safe place of work, a safe system of work, safe appliances for work and a safe and healthyworking environment.

Provide such information and instruction as may be necessary to ensure the health and safety at work of its employees, whilst promoting awareness and understanding of health and safety throughout the workforce and ensuring compliance with all relevant legislation.

Ensure safety and the absence of health risks in conjunction with the use, handling, storage and transportation of articles and substances.

Ensure the progressive identification and assessment of risks, and their elimination or control.

Provide employees with health surveillance where necessary.

Appoint competent personnel to ensure compliance with statutory duties.

Ensure the establishment, maintenance and development of arrangements for effective joint consultation on health and safety.

Prominently display the Certificate of Employer’s liability that covers employees for any death, injury or disease arising from their employment with the Company.

All workers employed by the Company are required to comply with and co-operate with the Company in its statutory duties. Failure to comply with health and safety duties, regulations, work rules and procedures may lead to dismissal from employment.

We expect all our workers and others affected by our undertakings to respect and adhere to this policy document.

Signed:

Board of Directors Responsible for Health and Safety

Dated:

2. ROLES & RESPONSIBILITES

It is the responsibility of every member of management to ensure that the safety management system is being implemented in his / her work area.

The responsibilities for all staff that perform health and safety duties are defined below. Every person performing a task is responsible for ensuring that it is carried out in accordance with the documented safe practices and procedures.

2.1 BOARD OF DIRECTORS

The Board of Directors (Board) have the overall responsibility for ensuring that the Genial Productions Health and Safety Policy is effectively implemented and that proper resources are available for this.

The Board will plan ahead as necessary to make human, financial and other resources available to secure a high standard of health and safety management, taking competent advice where relevant and will ensure that the Genial Productions Health and Safety Policy is effectively implemented in the respective areas of operation, and that adequate resources are made available to achieve this.

The Board will plan ahead as necessary to make human, financial and other resources available to secure a high standard of health and safety management, taking competent advice where relevant and will ensure that the Genial Productions Health and Safety Policy is effectively implemented in the respective areas of operation, and that adequate resources are made available to achieve this.

The Board have the responsibility of ensuring that our health and safety policies and the associated risk control procedures are suitable and sufficient. For devising an annual strategic health and safety plan with the assistance of our external health and safety consultants. (The annual strategic health and safety plan, developed by the Board, is concerned with establishing and maintaining the policy, organisation and culture necessary for effective risk control and as such it is a high-level executive activity).

Perhaps more than anything else, the Board is responsible for cultivating the commitment of the fellow Directors and other Heads of Department to a safety management system that will support staff and others at all levels.

The Board of Directors has the following responsibilities:

- There should be no explicit or implicit intention to obtain, retain or reward a business advantage

- It should comply with local law

- Providing leadership in health and safety to foster a positive health and safety culture.

- Factoring health and safety into decision-making.

- Ensuring that the Board is familiar with the policy and implements it.

- Ensuring that the Board is suitably trained to carry out delegated duties.

- Providing the final authority on matters concerning health and safety at work.

- Ensuring that responsibility for health and safety is properly assigned and accepted at all subordinate levels.

- Ensuring that the annual strategic Health and Safety plan is properly implemented.

- Monitoring health and safety performance by reference to the annual report.

- Remaining aware of the level of compliance with health and safety requirements and the standard of health and safety management within their areas of operation through systematic monitoring of health and safety performance.

- Ensuring that decisions taken on health and safety matters are based on competent risk assessments.

- Ensuring the correct assignment and communication of responsibilities down through the lines of management.

- Identifying and making adequate provision for the “on-the-job” health and safety training needs of all employees in the light of any new statistics or reports.

- Ensuring that any additional health and safety policies are prepared and put into effect, and that these are reviewed systematically and revised as necessary. These will supplement Genial Productions overall Health and Safety Policy by clarifying specific responsibilities and arrangements.

- Ensuring that effective means of communication and consultation on health and safety are established and maintained.

- Planning the management of health and safety, including all aspects noted above, in a systematic manner, then recording this plan and putting it into effect. This may require liaison with the Company Safety Advisor – our external consultants.

- Ensuring that the Health and Safety Policy is kept under review and revised as necessary.

- Establishing the annual strategy via the development of a strategic health and safety plan. This will include specific targets to implement health and safety policy and integrate this into the general business activity of Genial Productions.

- Ensuring adequate resources are provided to fulfil the objectives identified in the strategic and operational plans as agreed within the Health and Safety Committee.

- Developing an annual health and safety report.

- Reporting any Board decisions back to the Health and Safety Committee.

- Developing a structure for planning, measuring and reviewing health and safety policy.

- Developing a structure for implementing policy and supporting plans.

- Agreeing plans for improvement and reviewing progress to develop both the organisation and the policy.

- Producing written statements of general health and safety policy and strategic objectives for Genial Productions.

- Producing written statements on the organisation of planning, measuring and reviewing.

- Producing written statements on the organisation of implementation.

- Liaising with our external consultants where necessary, particularly with respect to inspections, reports, recommendations, changes in legislation and advice obtained from other parties.

- Ensuring that the Directors and Heads of Department are familiar with the policy and implement it.

- Monitoring the outputs of the Health and Safety Committee.

- Monitoring the implementation of operational plans.

- Endorsing, communicating and developing an overall health and safety policy, and insisting that high and continuously improving standards of health and safety performance are a key business objective.

- Maintaining a clear structure of accountability for health and safety at all levels, making clear that ultimate responsibility for health and safety rests with the Board. Also ensuring that every employee and business partner is competent and adequately resourced, and that the Board and all other parts of the organisation have access to competent advice.

- Insisting that corporate health and safety performance is adequately monitored – both actively by tracking key performance indicators (KPIs) and reactively through investigation of accidents, incidents and cases of work-related health damage.

- Periodically reviewing and reporting to stakeholders on progress and ensuring that lessons learned help ensure continuous improvement. This should incorporate the findings from monitoring and from independent auditing of health and safety management systems.

- Developing and maintaining personal competence to lead health and safety and keeping up to date with the risks associated with their organisation.

- Developing and maintaining personal competence to lead health and safety and keeping up to date with the risks associated with their organisation.

- Insisting that health and safety will be an integral part of all corporate activities, including dealings with other business partners, and that questions of health and safety will always be given priority.

- Insisting on full openness, transparency, consistency, proportionality, and fairness in all health and safety matters.

- Ensuring that, whether achieved by groups and/or individuals, outstanding health and safety performance is always recognised and rewarded.

- Leading by example by visibly supporting the development of a positive health and safety culture. This might include direct participation in health and safety activities, or simply ensuring that personal behaviour always supports corporate health and safety values and demonstrates acceptance of responsibility for corporate health and safety leadership

- Attend and Chair the Health and Safety Committee Meetings (as part of a rota).

- Endorse the minutes of the Health and Safety Committee Meetings.

- Develop, implement and monitor the annual strategic training plan.

- Approve the minutes and associated actions of the Health and Safety Committee.

- Seek feedback from colleagues on specific areas of concern.

- Monitor the service supplied by the Company Safety Advisor.

- Ensure that all employees receive adequate supervision, training, information and clear instructions to enable them to work safely.

- Ensure training courses are arranged for all staff, including Induction and special types of training.

- Arrange for Occupational Health medicals and health surveillance to be undertaken where necessary.

- Monitor the implementation of health and safety related concerns generated through staff supervision / appraisal sessions.

2.2 THE HEALTH & SAFETY COMMITTEE

The Health and Safety Committee provides a forum in which the senior management team can formulate and discuss company policy and its implementation. This forum also provides Genial Productions with a place to inform and consult with nominated Health and Safety representatives. This has been established in accordance with the terms of the Health and Safety at Work, etc Act 1974 and the Health and Safety (Consultation with Employees) Regulations 1996.

The Health and Safety Committee is made up of the following personnel:

- A Board Director that is Responsible for Health and Safety (Chair).

- Office Manager.

- Head of Production.

- Company Safety Advisor Representative.

- Administrator (Scribe).

The Company Safety Advisor representative attends by virtue of position, as may other external business consultants. As the Health and Safety Committee sees fit, it invites guest speakers to assist in its work.

Formal training for the Health and Safety Committee Members will be given and incorporated into the annual training plan by the Board.

The minutes will be endorsed by the Board

Meetings will be arranged by the Administrator and held in head office 4 times a year, with additional meetings convened to meet any special circumstances.

The Health and Safety Committee has the following responsibilities:

- Examine accident and incident trends, accident / incident investigations and any corrective action taken to prevent reoccurrence.

- Examine pro-active monitoring information and corrective action to be taken.

- Examine production review reports.

- Endorse and formulate health and safety targets.

- Consider documentation pertaining to Health and Safety presented to the company by external statutory authorities, the Company Safety Advisor or other external consultants.

- Consider documentation pertaining to health and safety presented by the Board or by Health and Safety Committee members.

- Assist in the development of structures / risk control procedures / other methods identified to control risks and help maintain these.

- Monitor the annual strategic health and safety plan and supporting operational plans to ensure the stated objectives remain on target.

- Monitor the adequacy of safety communication and publicity to employees.

- Monitor changes in legislation, regulations and guidance.

- Monitor and identify the allocation of resources for health and safety purposes.

- Keep the health and safety policy under review.

- Initiate audit reports and ensure actions are incorporated into strategic and operational plans.

- Report to company staff (including production personnel) on any changes to policy on practical issues that affect them.

- Put forward the views of staff (including production personnel) on matters pertaining to health and safety.

Each business unit representative has the authority to commit his or her business unit to an action.

Where a decision requires executive action, the Board presents its recommendation to the Board for their approval.

2.3 HEAD OF PRODUCTION

The Head of Production is responsible for implementing and enforcing the Health and Safety Policy and associated arrangements at production level.

The Head of Production has the following responsibilities:

- Attend the Health and Safety Committee meetings.

- Act as a point of contact for the Company Safety Advisor, Producers, Production Managers and/or Line Producers and Studios on all production safety related issues.

- Monitor the performance of, and line manage the activities of the Company Safety Advisor for production related issues.

- Liaise with the Company Safety Advisor to oversee management of vetting process of competent contractors.

- Monitor the implementation of the production health and safety plans.

- Ensure that Producers and Production Managers and/or Line Producers have a complete health and safety induction and understand their health and safety contractual responsibilities.

- Develop an annual supporting plan for the Board in conjunction with the Company Safety Advisor to meet strategic production related targets.

- Provide regular verbal feedback to the Health and Safety Committee on the actions identified in the Production Health and Safety Review reports (as prepared by the Company Safety Advisor) and distribute these as necessary.

- Sign off the Production Review reports.

- Write an annual production business unit health and safety report and present this to the Board.

- Ensure that production logs and risk assessment files are retained for the specified timescales.

- Carry out visits to production sites to monitor health and safety performance as necessary and appropriate.

- Monitor the performance of, and line manage the activities of the Company Safety Advisor for office / production office related issues.

- Hold the organisation’s accident book and records and ensure that accidents/incidents and the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995 (RIDDOR) reporting procedures are followed. This includes ensuring that reports are made to the enforcing body within the specified timeframe.

- Investigate accidents and incidents that are not reportable to the enforcing authority and prepare a report as necessary for the Health and Safety Committee.

2.4 OFFICE MANAGER

The Office Manager is responsible for administrating office related Health and Safety policy and enforcing the policies at office and induction level.

The Office Manager has the following responsibilities:

- Conduct office inductions for all new staff.

- Monitor office fire wardens and first aiders to ensure adequate cover.

- Develop and maintain office related security systems.

- Act as a point of contact for office related health and safety issues.

- Ensure all persons who work at weekends have adequate emergency procedure cover.

- Ensure lone working arrangements are adequate and monitor effectiveness of resources.

- Ensure the safe provision, use, maintenance and – as appropriate – inspection and/or testing of office work equipment.

- Take any measures found to be necessary for the proper management of health and safety.

- Seek competent advice on health and safety where relevant, including liaison with the Company Safety Advisor.

- Disseminate information on Health, Safety and Welfare within the organisation as appropriate on new legislation, hazards etc.

- Maintain the office health and safety notice boards.

- Coordinate the office inspections and supervise general administration arising from health and safety matters, giving the Board a report highlighting any apparent problems.

- Ensure that records are kept of all staff training, copies of all inspection/audit reports are retained and Accident/Incident/Ill health reports and statistics are archived.

- Compile for the Board an Annual report. This should include details on: the office training program, repairs and maintenance that are required in the interests of health and safety, office related safety procedures that need to be introduced, accident statistics, office-related revisions that are required to the organisation’s Health and Safety Policy and Codes of Practice.

- Ensure that an adequate stock of accident books is maintained.

- Investigate office related accidents that affect staff and take any necessary action to ensure that the circumstances are not repeated. This may be done in conjunction with the Company Safety Advisor where deemed appropriate.

- Produce and collate company Accident / Incident and Ill Health statistics on a quarterly basis and submit these to the Health and Safety Committee for discussion at the meetings.

- Liaise with Fire Authorities, Environmental Health Officers and other official bodies as appropriate.

- Monitor the office related safety performance of the organisation as a whole. Reference should be made to accident records, the use of first aid facilities, the length of time prior to action being taken on repairs and maintenance, reports from enforcement authorities, reports from nominated Staff Representatives and the Company Safety Advisor.

- Ensure that office related risk assessments are performed, reviewed and recorded as required by legislation.

- Hold and maintain a central file of office related risk assessments, ensuring that they are amended as and when required and reviewed annually.

- Retain and maintain office related health and safety documentation, duplicate records of which will be placed in a specific location within each office so that it can be easily obtained for enforcement inspections if necessary.

- Monitor the performance of contractors appointed to work in the office, in accordance with the laid down procedures and instructions.

- Physically inspect the area for which they have responsibility on a regular basis, completing a health and safety checklist of identified issues.

- Ensure that office related equipment, plant, materials and potentially hazardous substances have been checked and are safe, and that written instructions and procedures are available where necessary. If any equipment is found to be defective make sure it is rendered or labelled unusable until repaired. Arrange contracts for the servicing and maintenance of equipment by competent contractors as necessary.

- Ensure that First Aid boxes are located in an accessible position known to all staff, that they contain adequate supplies and are replenished after use, and that there are adequately trained first aid personnel in the office. Where staff are working on other sites ensure that a First Aid box is provided for their use.

- Ensure that office Landlords provide adequate welfare facilities in the form of toilets and fresh drinking water.

- Make checks to ensure that office Landlords have in place an asbestos register and perform the electrical testing and inspection of the main circuitry.

- Ensure that all fire alarms and emergency lighting are regularly serviced and maintained by the Landlord and that proper records are kept.

- Ensure that office related portable electrical equipment supplied by Genial Productions is electrically tested and inspected by a competent person, that all equipment is labelled and identifiable, and that proper records are kept of the test results. Ensure that re-testing occurs at the designated time and organise this wherever necessary.

- Conduct periodic visual / combined inspections on company supplied portable electrical appliances for the office.

- Identify a maintenance regime for work equipment supplied by the Company.

- Draw up emergency plans for the office.

- Conduct informal daily checks of office fire precautions to ensure they remain effective.

- Ensure that fire-fighting appliances are serviced and maintained by a competent contractor.

- Ensure fire escape routes are known to all staff and visitors and are free from obstruction.

- Give periodic verbal instruction to staff on the office fire evacuation procedure to maintain familiarity.

- Maintain the office health and safety library.

- Ensure an adequate stock of personal protective equipment is maintained.

- Arrange for display screen risk assessments to be carried out

- Issue Eye Sight Test Forms and Optometrist letters and vouchers where necessary to Users of Display Screen Equipment and submit payments to be made to Finance.

- Provide regular verbal feed back to the Health and Safety Committee on the implementation of the annual office Health and Safety plan.

- Ensure the maintenance of records and office related reports and retain these for the specified timescales.

- Ensure the administrator organises the quarterly Health & Safety Health and Safety Committee meetings. Produces minutes to be approved by all members of the Health and Safety Committee, making these available to the Health and Safety Committee within two weeks and placing them on the Intranet within three weeks.

2.5 COMPANY SAFETY ADVISOR

Our external consultants (as stated on the front page of this document) have been appointed as the Genial Productions competent source of health and safety advice. Their advice and assistance help ensure that adequate arrangements are made for effective planning, organisation, control, monitoring and training and for all other Health and Safety matters throughout the organisation.

The Company Safety Advisor will report via the Head of Production to the Board.

The Company Safety Advisor has the following responsibilities:

- Assisting Genial Productions in ensuring full and early compliance with health and safety legislation, including any new regulations, EU Directives or codes of practice, and making staff fully aware of any changes.

- Oversee a central record of accident, injury, sickness and near miss statistics, including causes of incidents and types of injury, and recommending any ways of avoiding recurrence.

- In conjunction with Board and local Management, ensuring adequate training of staff on health and safety matters.

- Offering advice on Health and Safety training to management and staff as required.

- Maintaining and updating the Genial Productions Health and Safety Policy Document at regular intervals.

- Working to create awareness among Genial Productions staff and contractors of the need for good health and safety practices.

- Consultation with local management to review protective and preventative measures throughout Genial Productions.

- Monitoring Genial Productions health and safety management system, including progress in implementing new or revised health and safety procedures.

- Auditing Genial Productions safety systems and performance.

- Assisting the Board with the development of an annual strategic health and safety report for Genial Productions.

- Providing a resource for the approval, monitoring and maintenance of the Company contractors list.

- Retaining and archiving the contractor documentation presented for approval onto the Genial Productions contractor list and ensuring that this can be easily retrieved within 48 hours.

- Compiling a bespoke Production Health & Safety Plan, Production Log, H&S Staff Handbook and Risk Assessment file for each and every production if required.

- Carrying out a production health and safety briefing session to handover the Production Health & Safety Plan, Production Log, H&S Staff Handbook and Risk Assessment File, and any other supporting documentation required on behalf of the Head of Production for each and every production.

- Acting as a point of contact for Producers, Production Managers and/or Line Producers regarding production safety issues as they arise.

- Acting as a point of contact for studios regarding production safety issues as they arise.

- Attending studio safety briefings, pre-production planning meetings and location planning meetings as appropriate.

- Conducting Production Manager and/or Line Producer briefings, de-briefings and signing off the Production Safety Log.

- Developing and signing off production related risk assessments as necessary.

- Monitoring the activities of the contractors appointed on production when required.

- Developing information sheets and risk control procedures as necessary.

2.6 LINE MANAGERS

Have a responsibility to ensure that the Health and Safety policy and supporting plans are implemented and actioned in the areas under their control. This includes the day-to-day overseeing of safe operations as part of their normal routine.

The Line Managers will ensure that the sector under their control is operated under safe and healthy working conditions. These responsibilities include:

- The identification and assessment, or making arrangements for the assessment, of significant risks to health and safety arising out of their sector, and the recording of these assessments.

- The establishment of safe systems of work in order to eliminate or minimise risks, and the communication of these systems and information about significant risks to employees under their control.

- Ensuring that all employees receive adequate supervision, training, information and clear instruction to enable them to work safely.

- The taking of any measures found to be necessary for the proper management of health and safety.

- The encouragement of joint consultation with employees, including making themselves reasonably available to receive and discuss health and safety queries raised by employees under their control.

- Co-operate with the Company Safety Advisor during the course of the investigation of accidents and near misses in order to take proper preventive action and to avoid recurrence as far as possible.

- Ensuring that the Company Safety Advisor will be actively involved in the assessment procedure whenever any new equipment, process or operation is commissioned. They will also consult with staff involved in the new process etc (and/or their representatives), in order to ensure that all reasonably foreseeable health and safety concerns have been properly considered.

- The seeking of competent advice on health and safety where relevant, including liaison with the Company Safety Advisor.

- Ensuring the correct allocation of responsibilities and the communication of these to all staff.

2.7 PRODUCER

The Producer has responsibility for the safe operation of the production. On a day-to-day basis this task may be delegated to the Line Producer and / or Production Manager, and help obtained from the Company Safety Advisor. However, the Producer will always have overall responsibility for the health and safety of the production as a whole.

The Producer must ensure that Genial Productions Health and Safety Policy and the Production Health and Safety Plan are properly implemented. Producers delegating any health and safety tasks, including those identified in the Health and Safety Plan, must ensure that those given such responsibilities are competent to carry them out. The holding of relevant qualifications, or attendance at relevant training courses may determine competence.

The Producer has the following responsibilities:

- Ensure that health and safety requirements are incorporated into the budget and that sufficient resources are supplied for its management.

- Implement the Production Health and Safety Plan and monitor this.

- Ensure that health and safety is a key subject discussed at all relevant production meetings (particularly during pre-production planning) and remain aware of health and safe related feedback from all production-appointed Heads of Department.

- Take advice from specialists in order that properly informed decisions may be made about the safe operation of the whole production.

- Ensure organisations or individuals selected to work on the production adhere to the Company’s Competent Contractor and Training Procedures.

- Ensure that risk assessments are completed for all aspects of the production and sent to the Company Safety Advisor for approval by the fastest practicable means prior to the activities taking place.

- Clearly identify who has responsibility for health and safety at the venue, studio or location.

- Have the authority to stop the work and take remedial action where a hazard or defect presents a risk to health and safety, particularly where there is danger to life or limb.

- Attend a post-production review meeting and develop a post-production review report in conjunction with the Company Safety Advisor.

2.8 LINE PRODUCER AND/OR PRODUCTION MANAGER

The Production Manager and/or the Line Producer is delegated the tasks of the Producer on a day-to-day basis insofar as they have more local control of the production. His/her responsibilities extend to ensuring that all persons involved in the production are aware of the bespoke H&S Production Plan produced for their production, along with all associated systems to support it.

The Production Manager and/or the Line Producer has the following responsibilities:

- Ensure that health and safety is taken fully into account when the production is scheduled and crewed, and that there are an adequate number of individuals on the production with up to date health and safety training.

- Ensure as far as reasonably practicable that all persons under his/her control have received adequate instruction to enable them to work safely, protecting themselves, their colleagues, property and plant. This involves circulating copies of risk assessments to all crew members via the call sheet or studio script, circulating the health and safety handbook and filing training records. Where appropriate, health and safety inductions may be held for all crew at the outset of production.

- Ensure that health and safety is a key subject discussed at all relevant production meetings (particularly during pre-production planning).

- Ensure that the production is operated under safe and healthy working conditions by completing risk assessments.

- Check that a risk assessment has been carried out and that all hazards have been identified and safeguarded against.

- Ensure proper instructions and information have been given to any persons likely to work with potentially harmful substances or be affected by them, particularly when any substance is used for special effects.

- Read and implement the information sheets / risk control procedures that are presented by the Company Safety Advisor.

- Ensure effective communication and co-ordination with the person(s) responsible for health and safety at the venue, studio or location throughout the production.

- Adhere to the Company’s Competent Contractor Policy and training requirements and attend a Production Health and Safety Log handover training session with the Company Safety Advisor.

- Implement and complete the Safety Log, the associated Risk Assessment File and the Production Health and Safety Plan that is developed by the Company Safety Advisor throughout the production process to demonstrate active health and safety management.

- Immediately bring to the attention of the Producer, the Company Safety Advisor and the Head of Production any concerns regarding the health and safety performance of any individual working on the production.

- Liaise with the relevant Heads of Department to ensure that safeguards and safe methods of operation are properly used and maintained.

- Have the authority to stop the work and take remedial action where a hazard or defect presents a risk to health and safety, particularly where there is danger to life or limb.

- Report all accidents and near misses to the Company Safety Advisor, irrespective of how minor, and bring serious accidents or incidents to the immediate attention of the Head of Production.

- Investigate accidents and near misses in order to take proper preventative action and ensure as far as possible that circumstances are not repeated. Contact the Company Safety Advisor in line with the accident reporting procedure as identified in the Production Log.

- Ensure that adequate supervision is available at all times, particularly where young (under 18 years of age) or inexperienced workers are concerned, and that all persons are encouraged to act safely and have general awareness of health and safety matters.

2.9 PRODUCTION COORDINATOR

The Production Coordinator acts as a health and safety administrator to the Production Manager and/or Line Producer. The role is also to oversee the adherence to the bespoke H&S Production Plan, the distribution of the H&S Handbook to all staff and crew, and the completion of the Production Log and relevant risk assessments (that are filed in the Risk Assessment File) as required for the production. If there is not a Coordinator allocated to a production, these responsibilities revert to the Production Manager.

The Production Coordinator has the following responsibilities:

- Coordinate contractor-vetting arrangements to ensure that all relevant documentation is requested from and received from contractors, and subsequently approved by the Company Safety Advisor.

- Maintain the Production Log and associated Risk Assessment File to ensure that they are completed and up to date.

- Ensure that all appropriate risk assessments are requested, completed and approved by the Company Safety Advisor, then distributed to all necessary persons and kept in the Risk Assessment File.

- Read, implement and distribute as necessary information sheets / risk control procedures that are presented by The Company Safety Advisor from time to time during production.

- Implement and monitor action points as identified in the Production Health and Safety Plan where requested to do so.

- Assist the Production Manager and/or Line Producer in the induction process carried out for all new production staff.

- Ensure that all the production personnel who will be ‘resident’ to some extent in the office receive an office induction by the Office Manager.

- Ensure that the cast and crew are given any relevant codes of practice and a copy of the appropriate induction Health and Safety Handbook.

- Ensure that an end of production de-brief takes place between the Company Safety Advisor and the Production Manager and/or Line Producer as soon as is practicable after the last shooting day.

2.10 LOCATION MANAGER

The Location Manager has the following responsibilities:

- Implement health and safety procedures and all safe-working practices in the areas under his/her control.

- Familiarise himself/herself with the Production Health and Safety Plan and the H&S Handbook and implement actions were asked to do so.

- Read and implement information sheets / risk control procedures that are presented by the Company Safety Advisor.

- Ensure, as part of preparation, that there has been regular and early contact with The Company Safety Advisor.

- Ensure that when selecting locations all potential hazards are considered and a location risk assessment completed and approved by the Company Safety Advisor.

- Ensure that the completed risk assessment for the location is given to the Production Manager and/or Line Producer and the Company Safety Advisor well in advance of any filming activity. This will enable any environmental hazards to have risk control initiatives allocated to them as part of the production generic risk assessment documentation.

- Act as Safety Coordinator on set, in conjunction with the First Assistant Director, and take responsibility for filming conditions on location.

- Ensure that all communication procedures and arrangements are in place when filming in public places. This may involve liaison with the Highways Department of the Local Council, Police and other emergency services, local Authority Film Offices, Venue Management etc.

- Keep relevant members of the public fully informed of all filming activities. In particular, neighbours and residents where location vehicles are to be parked in close proximity to their houses, garages etc.

- Ensure that safe working practices are adhered to and all crew and artists are fully aware of the risks associated with the location.

- Report to the Producer or Production Manager and/or Line Producer any accidents or near misses and take part in any investigation with a view to taking preventative measures.

- Carry out regular inspections of the location in order to identify any hazardous situations, and take action as required.

- Monitor the working practices of contractors to ensure that they are working in line with the content of their risk assessments and method statements.

- Ensure that the appropriate safety equipment PPE (personal protective equipment) such as hard hats and high visibility jackets are available and in good order and monitor that they are used at all relevant times as identified during risk assessment or in method statements.

- Maintain security on locations at all times.

- Ensure that he/she is personally competent in risk assessment techniques.Ensure that he/she is personally competent in risk assessment techniques.

2.11 DIRECTOR (PRODUCTION)

The Director has a general responsibility to give health and safety full consideration. In consultation with all other key personnel concerned with the production, the Director will take advice on health and safety matters and give them the same amount of consideration as any other issues.

The Director has the following responsibilities:

- Throughout the production the Director will, as far as reasonably practicable, remain aware of the health and safety aspects of the production and ensure that no persons are instructed to work in a manner that incurs an unacceptable risk to health and safety.

- Be fully aware of Genial Productions Health and Safety Production Policy and the content of the bespoke Production Health and Safety Plan.

- Read and implement information sheets / risk control procedures that are presented by The Company Safety Advisor.

- Remain aware of the systems and codes of practice that are put into place for the purposes of managing health and safety.

- Consult with the Company Safety Advisor in conjunction with the Production Manager or Line Producer in relation to the production risk assessments that have been prepared in order to contribute his/her personal professional expertise, experience and knowledge, or in relation to last minute good ideas / script changes before a shot is taken.

- Ensure that health and safety is not compromised in the interests of visual shots or continuity.

- Ensure that adequate rehearsal and/or planning time are built into any schedule dependent on the degree of risk, numbers of artists/ crew involved location constraints etc.

2.12 FIRST ASSISTANT DIRECTOR

The First AD has the day-to-day task of controlling the set. He/she is delegated the tasks as set by the Director and will, in the main, have responsibility for the filming conditions and act as Safety Coordinator on set.

The First Assistant Director has the following responsibilities:

- Liaise closely with the Location Manager to ensure the chosen locations are safe for the purpose of work.

- Give full consideration to health and safety when deciding how each shot is to be set up and recorded.

- Be fully aware of Genial Productions Health and Safety Production Policy and the content of the bespoke Production Health and Safety Plan.

- Read and implement information sheets / risk control procedures that are presented by the Company Safety Advisor.

- Consult with the Company Safety Advisor in conjunction with the Production Manager and/or Line Producer about the production risk assessments that have been prepared in order to contribute his/her personal professional expertise, experience and knowledge.

- Consider advice and information given by the Special Effects Supervisor and any other competent individuals (including stunt personnel) and ensure that the set is controlled in a manner that adheres to Genial Productions Health and Safety Policy.

- Not knowingly instruct any person to work in a manner that incurs unacceptable danger and, if in any doubt, report the matter to the Production Manager and/or Line Producer.

- Ensure adequate health and safety briefings have taken place including audiences, general public, crew at location and studio venues, artistes, extras etc. as applicable.

- Ensure that the shooting schedule has addressed all relevant health and safety issues, and that planning and rehearsal time to meet the degree of risk involved has been given full consideration.

- Liaise with the Production Manager and/or Line Producer to ensure all contractors are approved as competent, and that the necessary contractor health and safety documentation and risk assessments have been completed and approved, and that they are familiar with the content of the risk assessments before any activity commences on set.

2.13 PRODUCTION DESIGNER

The Floor Manager will, in the main, have responsibility for studio recording conditions and act as Safety Coordinator on the studio floor, including carrying out an audience safety briefing. He/she must report any concerns immediately to the Producer or Production Manager and/or Line Producer. It is vital that he/she has a good knowledge of the studio emergency procedures and means of escape and can brief the crew accordingly.

The Floor Managers has the following responsibilities:

- Ensure they have effective communication with the Company Safety Advisor and the relevant Heads of Departments.

- Ensure that designated escape routes are kept clear at all times.

- Ensure that fire exits, and fire points remain accessible at all times.

- Ensure that fire exit signs are visible and illuminated.

- Ensure that nothing obstructs the operation of fire shutters.

- Ensure that all threshold doors are closed.

- Ensure that no cables are placed on the floor directly in front of audience access doors.

- Ensure that studio stipulations regarding the drinking of water from cups or bottles on the studio floor are respected and adhered to.

- Ensure that the audience receives a health and safety briefing prior to recording.

2.14 FLOOR MANAGER

There are a number of important areas to identify, in terms of health and safety responsibilities, for the Audience Co-Ordinate. The below points relate to staff Audience Coordinators only. Any 3rd party Audience Support Services that are engaged for a production must be approved in line with competent contractor assessment procedures.

The Audience Coordinator has the following responsibilities:

- Ensure that all audiences have been given a full and informative health and safety briefing by either the Floor Manager or Warm Up Artist. This briefing will include emergency evacuation, medical assistance, overhead cranes, cables, smoking etc.

- Ensure that there has been full communication with the venue to ensure the health, safety and welfare of the audience. This communication should begin as early as is practicable through a studio visit and attendance at production meetings and should be followed up by correspondence confirming all arrangements.

- Ensure that there is adequate medical back up whenever audiences are required in the studio.

- Ensure that all Audience Stewards (Ushers) are conspicuously dressed so that they can be easily recognised by members of the audience e.g. wearing a tabard, coloured armband etc. (Although most venues now supply stewards as part of the hire charge, this does not delegate our health and safety responsibilities for audience safety).

- Ensure that there is an adequate ratio of Audience Stewards (ushers) to meet with the demands of the audience (see risk assessment). Consideration must be given to the requirements of the elderly, persons with special needs, children etc. This should be discussed at the production-planning meeting and should form part of the generic production risk assessment.

- Ensure that full consideration has been given to emergency procedures in respect of fire evacuation exits, assembly points, clearance of fire lanes, audience seating etc.

- Liaise with the studio to ensure that adequate security is in place and that all personal possessions have either been left in a supervised cloakroom or are safely stored under seats rather than being left in gangways, aisles etc.

- Regularly monitor the audience during the production to ensure that all rules regarding eating, drinking, smoking, leaving of coats etc. are being adhered to.

2.15 AUDIENCE COORDINATOR

There are a number of important areas to identify, in terms of health and safety responsibilities, for the Audience Co-Ordinate. The below points relate to staff Audience Co-Ordinates only. Any 3rd party Audience Support Services that are engaged for a production must be approved in line with competent contractor assessment procedures.

The Audience Coordinator has the following responsibilities:

- Ensure that all audiences have been given a full and informative health and safety briefing by either the Floor Manager or Warm Up Artist. This briefing will include emergency evacuation, medical assistance, overhead cranes, cables, smoking etc.

- Ensure that there has been full communication with the venue to ensure the health, safety and welfare of the audience. This communication should begin as early as is practicable through a studio visit and attendance at production meetings and should be followed up by correspondence confirming all arrangements.

- Ensure that there is adequate medical back up whenever audiences are required in the studio.

- Ensure that all Audience Stewards (Ushers) are conspicuously dressed so that they can be easily recognised by members of the audience e.g. wearing a tabard, coloured armband etc. (Although most venues now supply stewards as part of the hire charge, this does not delegate our health and safety responsibilities for audience safety).

- Ensure that there is an adequate ratio of Audience Stewards (ushers) to meet with the demands of the audience (see risk assessment). Consideration must be given to the requirements of the elderly, persons with special needs, children etc. This should be discussed at the production-planning meeting and should form part of the generic production risk assessment.

- Ensure that full consideration has been given to emergency procedures in respect of fire evacuation exits, assembly points, clearance of fire lanes, audience seating etc.

- Liaise with the studio to ensure that adequate security is in place and that all personal possessions have either been left in a supervised cloakroom or are safely stored under seats rather than being left in gangways, aisles etc.

- Regularly monitor the audience during the production to ensure that all rules regarding eating, drinking, smoking, leaving of coats etc. are being adhered to.

2.16 PRODUCTION ELECTRICIAN (GAFFER)

In health and safety terms the Production Gaffer is a vital Head of Department within the production crew. Gaffers must be up to date with their responsibilities and knowledge and have sufficient experience in either location and/or studio environments as appropriate. This will require evidence of competence, knowledge and experience.

The Gaffer has the following responsibilities:

- Ensure the safe installation of all electrical wiring including lighting circuits.

- Ensure the inspection and testing of all portable equipment brought onto the production by contractors, hire companies and crew has been carried out.

- Supervise the installation and use of all Residual Current Devices (RCD) used within the production, and in particular to ensure that these devices are operating within their designed parameters e.g. 30-millisecond cut out.

- Ensure contractors, e.g. Special Effects Supervisors, Stunt Co-ordinators, lighting, sound is utilising safe systems of work (isolation of supply and insulation of equipment, tools etc.)

- Ensure where applicable that the most up to date edition of the Institute of Electrical Engineers Regulations and Guidelines is being referred to for safe installation and working practices.

- Ensure when working in a public place that the safety of the public is paramount. All cables must be ‘safe by position’ so that no equipment is left exposed in such a manner that it can be tampered with. Particular care must be taken when working in the vicinity of children or those with special needs.

- Ensure that all stages, towers and rostra that require electrical feeds are earth bonded to protect all persons using electrical equipment from shocks.

- Liaise with venues/studio management/owners of domestic premises used as locations to ensure that the correct supply of electricity is available and to establish the maximum load capacity. This will reduce the risk of sudden power failure. The load bearing capacity of lighting grids should also be verified.

- Ensure all portable and vehicle generators are being used in the appropriate manner, have all safety devices, RCD, ECB in place and are working to the required standard of efficiency.

- Supply lighting risk assessments for approval by the Company Safety Advisor.

- If any lighting equipment is supplied by the Gaffer, CO2 fire extinguishers must also be supplied.

- Monitor lighting systems to ensure safety bonds are in use, lighting equipment has been PAT tested and the load bearing capacity of the lighting grids are not exceeded.

2.17 ALL EMPLOYEES

Everyone at work must take reasonable care for their own health and safety and that of others affected by what they do or do not do.

Employees have the following responsibilities:

- Co-operate with Directors, Line Managers and the Company Safety Advisor to ensure that safe and healthy working practices and workplace are maintained.

- Report promptly to their Line Manager and the Company Safety Advisor, as appropriate, any hazardous situation, defect, accident or near miss.

- Make full and proper use of any protective equipment or any other equipment with a health and safety function and keep such equipment in good order.

- Make proper use of the washing facilities and eating and drinking facilities provided so as to ensure high standards of personal hygiene where hazardous substances put personnel at risk.

- Act responsibly at all times.

- Co-operate with Genial Productions in the implementation and observation of all statutory requirements placed upon it.

- Observe the duty not to misuse or interfere with anything provided in the interests of health and safety.

- Individual employees are responsible for co-operating with management to meet the requirements of these arrangements. They must swiftly bring to their immediate manager’s attention any weaknesses in these arrangements so that additional control action can be implemented.

2.18 ALL SELF-EMPLYED PERSONS

All Self- employed persons have the following responsibilities:

- To take all reasonably practicable steps to ensure that they themselves are not put at risk, and that others who may be affected by their actions are likewise not put at risk.

- With respect to the legal regulations that require employers to protect their employees from risk, the same types of regulations apply to the self-employed, requiring them to protect themselves and others. These legal duties apply whether or not people accept and choose to comply with this policy.

- To make proper consideration of health and safety before embarking upon any work and will take reasonable care for their own health and safety and that of others at all times.

- Not to intentionally or recklessly interfere with anything provided in the interests of health and safety

- Adhere to specific legal requirements, such as assessing and adequately controlling risks to health before work commences.

- To give information about the health and safety aspects of their work to any person who might be affected by that work

2.19 SUB CONTRACTORS

Sub-Contractors have the following responsibilities:

- Have their own health and safety policy. However, those companies who employ fewer than 5 it is acknowledged that this does policy does not have to be written or recorded. Contractors however must, as Employers, keep to the “spirit and intention” of a policy and still have a legal duty to comply with all Health and Safety legislation as set out in the policy statement in section 1.0 of this document.

- Contractors, as Employers, must also assess and control any risks they create, and to inform all the other Companies with whom they share the work place what control measures they are adopting to minimise the risk of injury to other personnel. These assessments must be recorded if the Contractor employs more than 5 Employees

- To inform their Employees about risks to which they might be exposed when sharing the work place with them before work activities commence.

- Use their own tools and equipment (where practical) that are fit for their intended purpose and used in a safe manner.

- To assess the competency of and manage Sub-contractors under their control

- To monitor so far as is reasonably practicable the work activities of both their own Employees and those Sub- contractors under their control and remain generally aware of their health and safety performance.

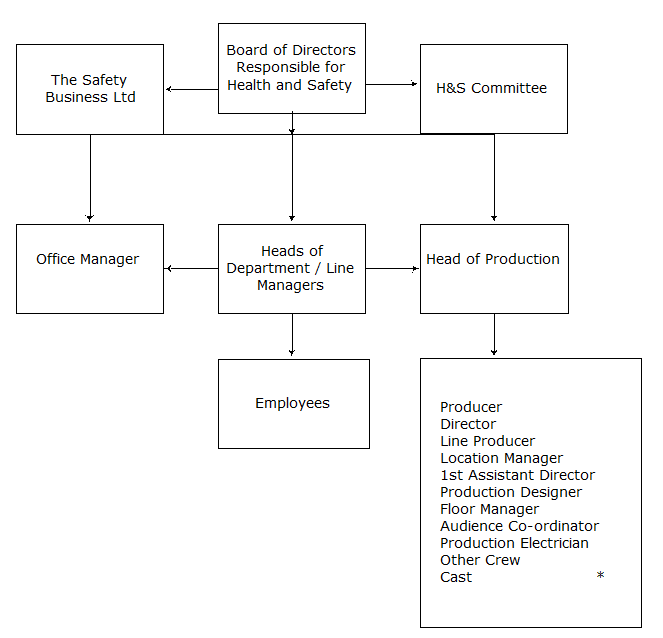

3. COMPANY HEALTH & SAFETY STRUCTURE

* Note, the number and variety of roles will vary from production to production and arrows go up and down.

4. HEALTH & SAFETY STRUCTURE

The arrangements below are supported by procedures that have been developed by the Company Safety Adviser and are to be carried out at a local level.

4.1 ACCIDENT REPORTING PROCEDURE

All staff have a duty to report accidents and incidents, no matter how minor, to their Line Manager as soon as possible in person, by phone or by email. Staff must also ensure that any accident or incident is recorded via the accident/incident reporting procedure, in which they will receive training.

All otherwise unrecognized hazards, sometimes illustrated by “near misses”, will be similarly reported and recorded.

Line Managers will identify any relevant incidents and ensure that the Office Manager is notified of these as appropriate.

All accidents that are entered in the Accident Book are to be reported to the Office Manager and the Company Safety Adviser, who will decide if further investigation is required.

All RIDDOR accidents, incidents and occupational diseases are to be reported directly to the Incident Contact Centre (ICC) based at Caerphilly by the Office Manager only. Under the RIDDOR Regulations the company is required to keep a record of incidents for inspection by visiting officers. To assist with this process, once reported to the ICC a copy of a report will be sent within 7 days to the company, and the company is given the opportunity to correct any errors in it.

4.1.1 FORMS

An official Accident Book, in which details of all accidents/occurrences must be inserted, will be issued for each production. Each office should also have its own accident book. A copy of each entry should be sent to the Office Manager and the Company Safety Advisor.

Accident, incident, occupational disease and RIDDOR records should be examined on a quarterly basis by head of department, to ensure and confirm that all accidents are being reported in the appropriate manner.

4.1.2 STEP BY STEP REPORTING PROCEDURE

- An accident, incident or occupational disease is reported by staff to the Line or Location Manager, who should then inform the Head of Production and the Company Safety Advisor.

- As necessary, first aid treatment is administered to the casualty by the appointed first-aider / the casualty is taken to hospital / the casualty consults their GP, etc.

- A formal record of the accident, incident or occupational disease is entered into the accident book. In the case of an occupational disease written confirmation from a doctor is required.

- The entry is signed and dated by the person making the entry in the book to confirm that it is a true and accurate record.

- The entry is signed and dated by the casualty or the member of staff who has reported the incident. If the casualty is unable to sign and date the book due to injury this will be carried out upon their return to work.

- Witnesses are required to sign and date the accident book below the signature box of the person who has had the accident to confirm that it is a true and accurate record.

- Details of how the accident / incident / occupational disease occurred are recorded on the accident form by the Line Manager (or Senior Management in the Line Manager’s absence).

- In all cases the Company Safety Advisor is contacted for advice.

- The Head of Production will report the incident to the Incident Contact Centre if the incident falls within the requirements of RIDDOR.

All RIDDOR F2508/A incidents are to be reported to the following address:

Incident Contact Centre

Caerphilly Business Park

Caerphilly CR83 3GG

For Internet reports see www.riddor.gov.uk (or link via the HSE www.hse.gov.uk)

By telephone (charged at a local rate): 0845 300 9923

By fax (charged at a local rate): 0845 300 9924

By email: riddor@natbrit.com - Where appropriate, the Line or Location Manager (with such assistance as they require) interview the casualty and witnesses to discuss the incident.

- An investigation relating to the underlying cause of the accident is arranged by the line manager, location manager or senior manager, in line with the Accident Investigation procedure outlined in this health and safety policy document.

- Accidents involving members of the public or non Genial Productions’ employees must also be reported to the line or location manager. If this person is taken by ambulance to hospital from the site it should be reported by the Head of Production as a RIDDOR notification to the Incident Contact Centre.

4.1.3 ACCIDENT INVESTIGATION

Line or Location Managers have the responsibility of investigating accidents that affect their staff, work area or work activity (including accidents to contractors, visitors, passers-by or even trespassers).

In complex or serious cases, or those which fall within the Reporting of Injuries, Diseases, Dangerous Occurrences Regulations 1995 (RIDDOR) the Company Safety Advisor will carry out an investigation.

Genial Productions has adopted a documented Accident Investigation procedure (below), which outlines the accident investigation process. Accident investigations will be conducted in accordance with this written procedure at all times. The Accident Investigation Form is used to record all relevant information, both from the immediate preliminary investigation and any necessary subsequent detailed investigation. Checks have been put in place to ensure that the Line or Location Manager has been trained in both accident investigation, notification and reporting techniques if not training will be arranged. The Company Safety Advisor will co-ordinate and carry out the accident investigation, notification and reporting techniques in conjunction with the Line or Location Manager or the Office Manager were office related.

The objective of accident investigation is to establish the underlying root causes and to identify actions that should prevent or significantly reduce the risk of a recurrence. Senior Managers shall become actively involved in the investigation of serious or high-profile accidents.

- Serious accident / incident reported.

- Director of Production contacts Company Safety Advisor – discussion held.

- Implications for company identified – civil / criminal.

- Investigation

- Accident report produced.

- Actions and recommendations actioned.

4.1.4 REVIEW

Task analysis, procedures, work instructions and safety rules shall, as appropriate, be reviewed following accidents. Risk assessments shall be examined, and a reassessment undertaken in accordance with the relevant risk assessment procedure. Corrective actions will be identified and prioritised. The relevant manager(s) will incorporate these corrective actions into their operational plans.

Corrective actions identified during accident investigations will be submitted to the Health and Safety Committee and / or Safety Performance Groups for monitoring and consultation purposes.

4.2 ARRANGEMENT FOR PLANNING AND IMPLEMENTING POLICY

4.2.1 DEPARTMENTAL SAFETY REVIEW

At Production and Department level, the Board / HOP / Line Managers will ensure that the policies are being adhered to. This could be via regular update meetings or via specially arranged meetings to assess any new issue.

4.2.2 FORMULATION & DEVELOPMENT OF POLICY

It is the responsibility of the Board to develop and install the safety management system, using the Company Safety Advisor as the company’s source of health and safety advice and assistance.

4.2.3 EXECUTIVE STATEGIC PLANNING & TARGETS

An annual health and safety strategy are developed by the Board in conjunction with the Company Safety Advisor. This is concerned with establishing and maintaining the health and safety policy, along with creating an environment in which effective risk control can take place. The annual strategic health and safety plan contains easily identifiable, achievable objectives and is formally approved by the Board and the Board prior to implementation.

The strategic planning meeting held between the Board and the Company Safety Advisor is held annually and organised to establish and achieve the following outcomes:

- Establish priorities for executive health and safety objectives

- Identify and address any outstanding objectives from the previous year’s health and safety plan

- Set achievable and easily identifiable annual targets

- Produce an overview of how to support the policy and targets

- Produce an annual strategic health and safety plan to support the Company’s executive health and safety targets

- Allocate resources to achieve these targets and to control any risks identified

4.2.4 DEPARTMENTAL PLANNING & TARGETS

Departmental planning and targets are concerned with meeting the executive targets set by the annual strategic health and safety plan, assessing the risks arising from the Company’s activities and maintaining risk control measures.

Line Managers will use Health and Safety Committee, Team Safety Performance Groups, input from safety representatives, feedback from training and appraisal sessions, and suggestions from staff to encourage their department employees to become involved in the planning process. They will manage this process by developing departmental plans with the following goals in mind:

- Establish priorities for executive health and safety objectives.

- Produce an overview of how to support the executive policy and targets.

- Set achievable and easily identifiable operational targets.

- Produce executive operational plans to support the targets.

- Allocate and / or request resources to achieve these targets and to control identified risks.

- Present this plan to the Board and Health and Safety Committee on an annual basis.

Line Managers will also be required to develop and present an annual health and safety report based upon the implementation of the plan to the Health and Safety Committee and the Board.

4.2.5 PRODUCTION PLANNING & TARGETS (H&S PLANS)

Production planning and associated targets are concerned with achieving the Production Department’s targets. A production plan has been incorporated into the Production Log and will be developed for each production by the Line Producer or Production Manager and presented to the Producer. The plan will be implemented at a local level by the Production management team.

The Head of Production will monitor the implementation of the production plan for the duration of the production, and feedback will be incorporated into the production review report produced by the Company Safety Advisor and presented to the Health and Safety Committee.

4.3 AUDIT

At suitable intervals (and probably at intervals of two or more years) The Board will commission The Company Safety Advisor to examine Risk Productions entire organisation – from a health and safety perspective – to test whether Risk Productions is meeting its safety aims and objectives.

The audit will provide an analysis of our strengths and weaknesses and examine the effectiveness and efficiency of:

- Leadership

- Hierarchies

- Safety planning processes.

- Decision-making.

- Delegation

- Policymaking

- Policy implementation.

- Monitoring

The report of the audit will be considered by a special meeting of the Health and Safety Committee.

4.4 COMMUNICATION

The manager responsible for each building, studio or location is responsible for issuing and displaying, as appropriate, the emergency arrangements. All staff working in a place are trained in responding to emergency situations as part of the induction programme.

Mobile staff will carry with them a list of telephone numbers necessary or useful in an emergency.

4.5 COMPETENCE

4.5.1 PROVISION OF INFORMATION TO ENHANCE COMPETENCE

Genial Productions will liaise with external bodies e.g. the Company Safety Advisor or the Health and Safety Executive to ensure that relevant, up-to-date, health and safety information and advice is obtained.

The company ensures that all staff are provided with relevant information on:

- Standards, guidance and legal requirements

- Feedback on the outcome of planning, measuring, reviewing and audit of their risk control procedures

- Contractor cooperation and coordination arrangements

- Emergency arrangements

- Any specialist training or qualification needed to do the job safely

- Health surveillance monitoring techniques implemented to control risk

4.5.2 PROVISION OF TRANING AND INDUCTION

An annual Health and Safety training plan will be developed for Genial Productions staff by the Board. This plan will be monitored by the Board, the Health and Safety Committee and Heads of Departments to ensure it remains on target. All training takes place in work time with no loss of earnings to staff.

Training plans are developed annually and will incorporate:

- Induction

- Legal requirements

- Training standards as advised by the Company Safety Advisor

- Risk control measures which have been identified as part of the risk assessment process

- New or specialist training

- Special needs of staff

- Pregnant workers

- Young persons

- Those returning to work after sickness or ill health

- Those transferring from one job to another

Individual safety capabilities of staff are identified during the recruitment and selection process. Evidence of any formal health and safety training attended prior to engagement will be held on the individual’s personal file to act as a formal record of their competence and retained by the Office Manager.

All staff will be briefed or trained on relevant health and safety policies and procedures within two working days of joining Genial Productions. An additional induction training session will be given to production personnel at a local level and any specialist training identified by the Line Manager or the Company Safety Advisor during pre-production.

Staff will also receive personal copies of the following health and safety handbook/s during the course of the induction training session as appropriate:

- Genial Productions Induction Handbook

- Studio Related Codes of Practice and Information – Issued by the Studios

Formal training as appropriate to job specification and risk is included in the induction briefing / annual training plan and as part of the core competencies for staff and senior management. Records of such training are retained by the Board and in the Production Log, and a relevant entry will be made in the individual’s personal file where appropriate.

4.6 CO-OPERATION & CONSULTATION

The Health and Safety Committee has been established under the provisions of the Health and Safety (Consultation with Employees) Regulations 1996 and is an advisory group to the Board and the Board.

The company seeks to enable the active involvement of staff in implementing its policies and procedures on health and safety at work. The company will give full support to:

- Appoint staff Health and Safety Representatives

- Provide Health and Safety Representatives with the information and training necessary to carry out their functions

- Provide facilities to enable the Health and Safety Representatives to carry out their functions

- Involve staff or their representatives in the assessment of significant risks and the development of risk control measures

- Involve staff or their representatives in Safety Performance Groups

4.7 DISCIPLINARY PROCEDURE

Where necessary, the management of health and safety will be supported by appropriate use of the disciplinary process.

Employees who refuse to co-operate with safety management may become subject to the escalating process of verbal and written warnings. Such action might be triggered by, for instance, refusal to follow safe operating procedures, refusal to wear personal protective equipment, refusal to conduct risk assessments, etc.

Similar action may be taken against staff who act with a significant lack of care for the safety of others or themselves.

Extreme cases, such as dangerous behaviour, transparently inadequate risk assessment, ordering others to act in a dangerous fashion, etc, may even lead to dismissal.

4.8 DOCUMENT & DATA MANAGEMENT

Provision has been made to ensure that documentation relating to health and safety is adequately controlled. The issue, control and recall of all documents shall be the responsibility of the Office Manager. For the effective functioning of the safety management system, the most recent procedures shall be posted on the intranet and distributed by the Office Manager to those staff listed as holding paper copies. Every intranet document shall carry a date mark.

Every document shall have a unique title, document number and issue number. They shall be approved and signed by the appropriate Line Manager or the Board, as applicable.

All changes to documents shall be implemented in writing and as per the Quality System Procedure, then processed in a manner that ensures prompt action at the specified locations. Records shall be maintained of changes as they are made. Documents shall be revised and re-issued, as a new edition, after a practical number of changes have been issued.

A master list has been established by the Office Manager to identify the current version of health and safety documents in order to preclude the use of non-applicable documents. Provision has been made to remove and recall all obsolete documents.

When required for legislative or “traceability” purposes (accident report forms, risk assessments etc.) copies of each superseded document will be retained and archived by the Office Manager.

4.9 FIRE

A Fire Risk Assessment will be carried out as arranged by the Company Safety Advisor for office premises that are under the control of Genial Productions and where Genial Productions has been identified as the ‘responsible person’ which will be reviewed annually.

An assessment of the fire risks on the production is a statutory obligation and will be completed by a competent person, preferably at the planning stage or at least as one of the first jobs after occupation of a premises

The manager responsible for the building will liaise with the managers responsible for the work in order to assess and control fire risks.

An assessment of the fire risks on the production is a statutory obligation and will be completed by a competent person, preferably at the planning stage or at least as one of the first jobs after occupation of a premises.

The manager responsible for the building will ensure the significant findings of the fire risk assessment and the additional control measures are properly recorded and will prepare an emergency plan.

Fire Extinguishers appropriate for the hazards and risks within buildings/on location will be provided, being wall mounted where appropriate. Designated staff i.e. Fire Wardens will be trained in their use. On location risk assessment(s) will identify the level of provision and the individual required to provide the necessary extinguishers i.e. Gaffer. All extinguishers will be serviced and maintained annually by a competent person.

4.9.1 FIRE WARDENS

The Fire Warden has responsibilities both to prevent fire and in the event of a fire starting.

To aid the prevention of fire Genial Productions’ Fire Wardens will:

- Become familiar with fire zones, escape routes, fire point etc.

- Ensure that fire escapes are known to all staffs and visitors, and that escape routes are free from obstruction.

- Check that safety signs, fire points and fire routes do not become obstructed by set dressing or equipment.

- Ensure that firefighting equipment and methods of raising the alarm are not interfered with or moved.

- Report any suspected fire hazards immediately to the First Assistant Director or other appointed Line Manager.

- Implement the bomb procedure when it has been identified as responsible to do so.

In the event of a fire being discovered, a Fire Warden will:

- Raise the agreed alarm and ensure that people respond correctly to the alarm in the event of a need to evacuate the building.

- Ensure that persons are evacuated from their designated area of set and are sent to a place of safety and notify other tenants of the need to evacuate.

- Search their fire zone thoroughly to ensure that everyone has left the building – do not forget toilets and other rooms not frequently used.

- Tackle only a VERY MINOR fire using the correct type of extinguisher for the type of fire in question However, if the fire is established they will not attempt this. Once they have left a fire, they must leave the building whether they believe it has been extinguished or not and must not return to it. The Fire Brigade will check if it is really out.

- Liaise with the Fire Brigade as required.

- NOT go into any areas containing smoke or an established fire. If he/she finds a door that is closed, he/she is to feel it with the back of their hand and if it is hot is NOT TO OPEN IT.

4.10 HEALTH SURVEILLANCE & PROMOTION

Where it improves general or individual health without undue imposition on the individual, appropriate programmes of health surveillance will be instituted. Health checks will be managed by external consultants. These consultants will report to Genial Productions via the Board, advising on the:

- Rates of participation.

- Indications of harm to health.

- Individuals at particular risk.

The consultants will only provide information on identifiable individuals where each individual has provided written consent.